5: CRDC Global – Building a Better World

Most consumers are aware of the numbering 1 to 7, embedded in the recycle symbol under plastic items and they diligently put them in recycling bins. The numbers denote the type of plastic so that they may be recycled appropriately. The truth of the matter is that only the number 1 and 2 are easily recyclable and rest end up in the landfills. We ask our guest Donald Thomson, Founder and CEO OF CRDC Global (Center for Regenerative Design Collaboration) what happens to the numbers 3 to 7 and how they can be successfully recycled. In this episode, Donald shares how CRDC started as a simple program “Bag that Builds” that encouraged school children to collect the plastics from their homes to a now patented technology that offers a global solution.

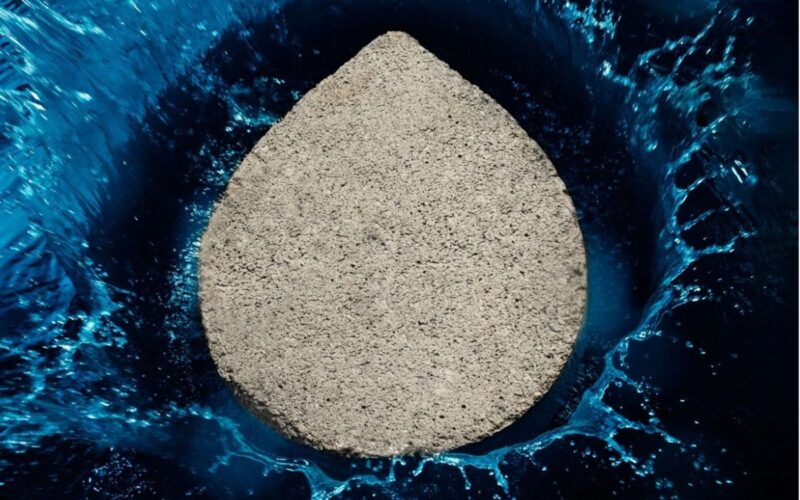

Their expertise lay in construction projects and the realization that the construction industry contributes around 38% of the CO2 emissions led them on the mission to reduce CO2 emissions of their projects. Their patented technology enables them to use the plastics number 3 to 7 to manufacture s lightweight yet durable aggregate to be added cement- that means they can utilize all kinds of plastics even multi – layer plastics.

CRDC is a mindful company that employs REAP (Recover – Enrich – Appreciate – Prosper) – an approach that is based on a collaborative net-zero circular economy model that views the plastic and construction industries as a connected system to create inter-relationships between these industries where the plastic industry waste stream becomes the raw material and value stream for the construction and building industry. Learn about this fascinating technology and their approach to the market to bring maximum impact to the problem of recycling plastics.

https://crdc.global

https://mindfulbusinessespodcast.com/

#recyclingplastics

#recycling

#mindfulbusinesses

#CRDC

#bagthatbuilds,

#circulareconomy

#co2emmisions

#netzero

#construction

#sustainablecement