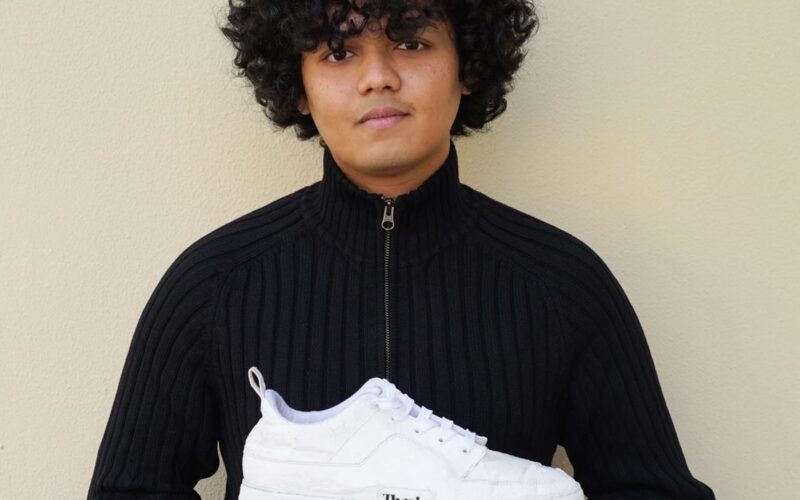

78: Thaely – Don’t Just Do It – Do It Right

We talk with Ashay Bhave, founder of Thaely, who as a middle-schooler dreamt of becoming a sneaker designer. His journey begins at the Fashion Institute of Technology, New York, where disenchanted within the first year, he returned back to Dubai to pursue a degree in business at Amity University. As a designer Ashay wanted to solve problems – the problem of plastic grocery bag waste – we consume 3 trillion of them annually. After some near fires in his kitchen, he developed a product Thaely Tex. Thaely is made with 100% recycled raw materials. Each sneaker uses ThaelyTex that’s made using 10 upcycled waste plastic bags. ThaelyTex is made in collaboration with TrioTap Technologies in Gurugram, India. The waste plastic bags are collected from housing complexes, offices, and stores from in and around Gurugram, India. The lining is made with rPET (Recycled Polyethylene Terephthalate is a fabric made from recycling waste PET Plastic Bottles) using 12 Recycled waste plastic bottles. With their partnership with The Shoe Laundry, the sneakers are either refurbished or recycled. Each pair is also packaged in a reusable rPET. Every component of the shoe and its process is looked into great detail to achieve Thaely’s sustainability goals. Come along and learn more in this episode.

Read More